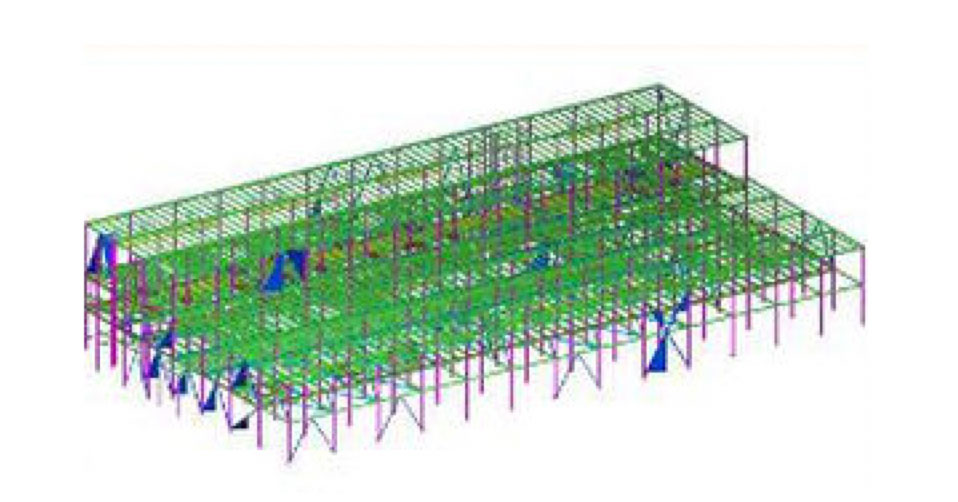

- Boeing 787 Dreamliner Plant

- 174 Meeting Street

- Yokohoma Tire

- Cherokee Indian Hospital

- EFACEC Power Transformer, Inc.

- Gulfstream Aerospace Corp.

Using the design/build project delivery method, engineers along with our project management team, were able to exceed the customers design criteria and top out the steel, just 10 months after the design.

- 18,000 tons of structural steel

- 636,540 sq. ft. of roof deck

- 618 ft long trusses

- 10,000 bolts/truss used

- 460 ft truss clear spans

- 1,283,000 sq. ft. facility

174 Meeting Street

Charleston, SC

Located in historic downtown Charleston, 174 Meeting Street had some unique challenges. The building was positioned on a long, narrow plot of land with large windows and openings on each end.

-

4-story class “A” commercial office

-

52,000 sq. ft. of office space

-

320 tons of structural steel

-

Special concentrically braced frames and special moment frames